3D food printing on the menu for summer scholar

A Lincoln undergraduate has had a taste of a new concept in food production after completing a 10-week summer scholarship using 3D printing technology on campus.

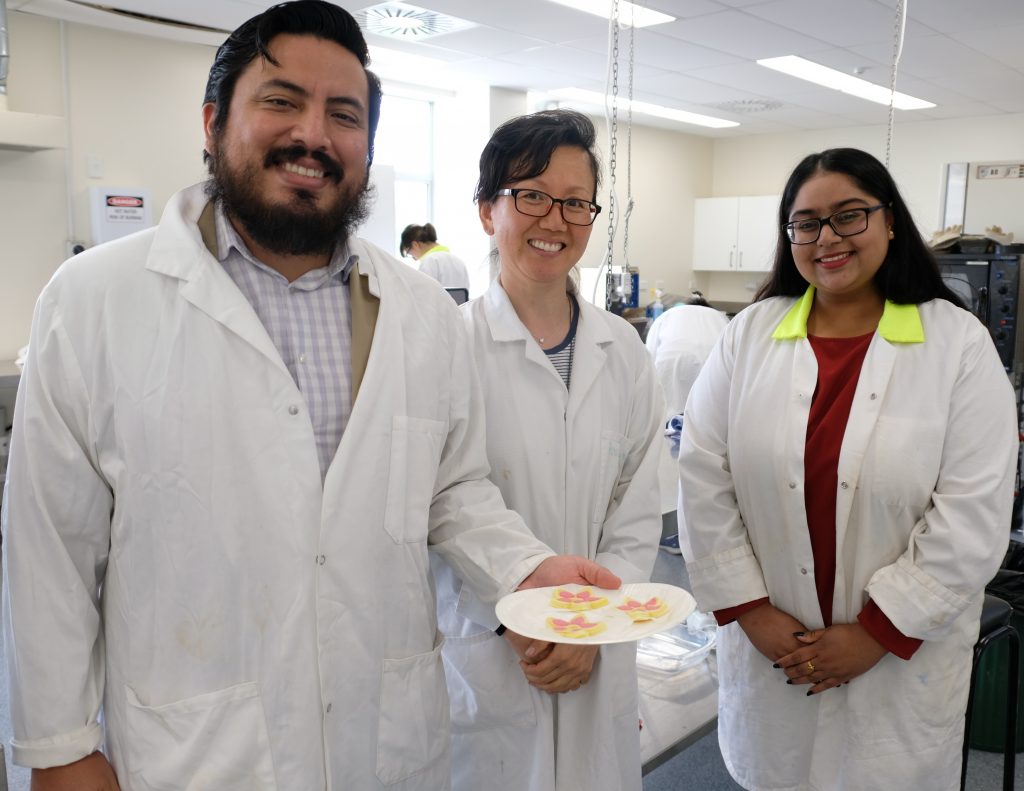

Sahiti Peddisetti, who is about to begin her final year of a Bachelor of Science (Food Science), was tasked with creating 3D reconstructed food products from low value cuts of meat and additional natural ingredients, such as plant-based protein.

The pilot study involved producing new foods in a range of shapes, textures and colours via a 3D food printer, allowing her to experiment with different ways of reshaping the materials into desirable products.

Sahiti’s supervisors, Drs Hannah Lee and Damir Torrico, say the project has important implications for sustainability, as increasing available protein in foods can reduce waste and fully utilise existing animal and plant-based proteins by improving their functional and nutritional value.

The reconstructed foods that Sahiti created used tough, low-value meat cuts, with the addition of pea plant protein isolate and gelatine.

“Our findings have shown that the tenderness of different 3D printed, cooked beef cuts follow the same trend as normal, cooked beef cuts,” Sahiti said. “For example, beef blade tends to be less tender than beef rump, in both normal and 3D printed conditions.

“From a sensory perspective, the 3D printed, cooked beef samples were identified as ‘dry’ and ‘easily melting’ with a ‘strong beef flavour’. This was directly related to the meat preparation and cooking methods, which involved freeze drying of meat and conventional methods of cooking.

“In the future, we would like to use techniques that can easily transform meat cuts into puree, ready to use for printing. This way, we wouldn’t lose the meat’s original qualities.”

The pilot study leads into a research project with Massey University, which will involve Dr Lee and other Lincoln academics developing tools and prototypes for the food industry to produce protein ingredients that are new to the country.

“The New Zealand government’s vision of Food Transition 2050 emphasises diversification, so there is increased attention on animal and non-animal protein,” Dr Lee said.

“A review of 3D printing of animal products has suggested this technology can offer the opportunity to produce complex shaped foods with increased functional and nutritional value. The quality of a protein depends not only on the composition of essential amino acids but also on its bioavailability.

“This is determined by digestibility, the proportion of food’s nitrogen that is absorbed after ingestion.

“There is an urgent need to expand our understanding of how the pre and post printing processing of 3D printed protein constructs will affect their behaviour in the gastrointestinal environment.”

Dr Lee said the Department of Wine, Food and Molecular Biosciences at Lincoln University had recently invested in several 3D food printers from Foodini, manufactured by Natural Machines, for the purposes of carrying out this kind of work.

“The scholarship was a great way to give an undergraduate food science student the opportunity to experiment with the technology and gain crucial skills in this developing area.”

Sahiti was delighted that the scholarship combined her main interests in science – food and sustainability.

“I have learnt many valuable skills, such as approaching a research question, designing research methods and working with 3D printers,” she said. “The scholarship has given me a feel for what is like to work in a research environment. I had a lot of fun with the printer, just playing around with different shapes and printed foods with various textures.

“Since the concept of 3D printed meat is still new to the food industry, I am very happy that I have been a part of leading research in such novel areas at Lincoln.”

The study was part of a range of 10-week summer scholarships available through the Faculty of Agriculture and Life Sciences. Each are valued at $6,000.

A Lincoln team, including Dr Lee and Professor Jim Morton, are now embarking on the year-long project with Massey University to design 3D printed foods from animal, plant and hybrid proteins. Massey academics will use their expertise in the in vitro protein digestion system to conduct nutritional evaluations of the selected foods.